L298N Motor Driver Module – 2A Dual Channel

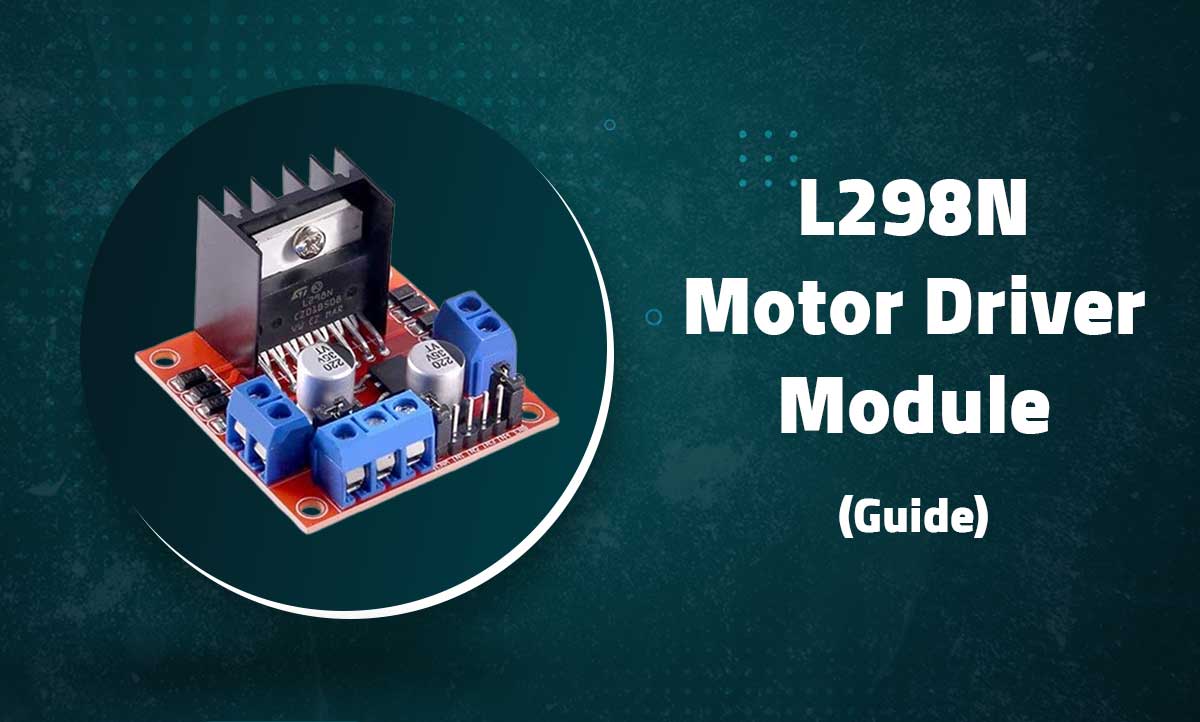

L298N Motor Driver Module

2A Dual Channel H-Bridge for DC and Stepper Motors

Introduction

The L298N is a high-voltage, high-current dual full-bridge driver designed to control inductive loads like DC motors and stepper motors. This module can drive two DC motors bidirectionally or one stepper motor with up to 2A per channel.

Key Features

High Power

2A continuous current per channel

Bidirectional

Full control of two DC motors

Wide Voltage

5V-35V operating range

Multiple Control

PWM speed + direction control

Technical Specifications

| Driver IC | L298N Dual H-Bridge |

|---|---|

| Operating Voltage | 5V – 35V DC |

| Peak Current | 3A per channel (2A continuous) |

| Logic Voltage | 5V (compatible with 3.3V MCUs) |

| PWM Frequency | Up to 25kHz |

| Power Dissipation | 25W (with heatsink) |

| Control Signals | TTL/CMOS compatible |

| Dimensions | 43mm × 43mm × 27mm |

Pin Configuration

| Terminal | Function | Connection |

|---|---|---|

| +12V | Motor Power (5-35V) | Battery positive |

| GND | Ground | Battery negative |

| +5V | Logic Power (optional) | 5V (if jumper removed) |

| ENA | Channel A Enable | PWM capable pin |

| IN1/IN2 | Channel A Control | Digital pins |

| IN3/IN4 | Channel B Control | Digital pins |

| ENB | Channel B Enable | PWM capable pin |

| OUT1/OUT2 | Channel A Motor | Motor A terminals |

| OUT3/OUT4 | Channel B Motor | Motor B terminals |

Note: Keep the jumper on +5V terminal if using the onboard 5V regulator

Wiring Diagrams

Basic DC Motor Control

// Motor A connections

const int enA = 9;

const int in1 = 8;

const int in2 = 7;

void setup() {

pinMode(enA, OUTPUT);

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

// Initial state - motor off

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

}

void loop() {

// Rotate clockwise at full speed

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

analogWrite(enA, 255); // Full speed

delay(2000);

// Rotate counter-clockwise at half speed

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

analogWrite(enA, 128); // Half speed

delay(2000);

// Motor brake

digitalWrite(in1, HIGH);

digitalWrite(in2, HIGH);

delay(1000);

// Motor stop

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

delay(1000);

}

Stepper Motor Control

const int stepsPerRevolution = 200; // Change for your stepper

const int in1 = 8, in2 = 7, in3 = 6, in4 = 5;

int stepDelay = 5; // ms between steps

void stepMotor(int step) {

switch(step) {

case 0: // 1000

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

break;

case 1: // 1100

digitalWrite(in1, HIGH);

digitalWrite(in2, HIGH);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

break;

case 2: // 0100

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

digitalWrite(in3, LOW);

digitalWrite(in4, LOW);

break;

case 3: // 0110

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

break;

case 4: // 0010

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, HIGH);

digitalWrite(in4, LOW);

break;

case 5: // 0011

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, HIGH);

digitalWrite(in4, HIGH);

break;

case 6: // 0001

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

break;

case 7: // 1001

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

digitalWrite(in3, LOW);

digitalWrite(in4, HIGH);

break;

}

}

void setup() {

pinMode(in1, OUTPUT);

pinMode(in2, OUTPUT);

pinMode(in3, OUTPUT);

pinMode(in4, OUTPUT);

}

void loop() {

// Rotate CW

for(int i=0; i<stepsPerRevolution; i++) { stepMotor(i % 8); delay(stepDelay); } delay(1000); // Rotate CCW for(int i=stepsPerRevolution; i>0; i--) {

stepMotor(i % 8);

delay(stepDelay);

}

delay(1000);

}

Tip: For better performance, use the AccelStepper library instead of manual stepping

Advanced Features

Current Sensing

float readCurrent(int sensorPin) {

int rawValue = analogRead(sensorPin);

float voltage = rawValue * (5.0 / 1023.0);

float current = voltage / 0.1; // 0.1Ω sense resistor

return current;

}

void checkOverCurrent() {

if(readCurrent(A0) > 2.0) { // 2A threshold

digitalWrite(enA, LOW); // Emergency stop

Serial.println("OVER CURRENT!");

}

}

Acceleration Control

void smoothStart(int motorPin) {

for(int i=0; i<=255; i+=5) { analogWrite(motorPin, i); delay(50); } } void smoothStop(int motorPin) { for(int i=255; i>=0; i-=5) {

analogWrite(motorPin, i);

delay(50);

}

}

Serial Control

void processSerialCommands() {

if(Serial.available()) {

char cmd = Serial.read();

switch(cmd) {

case 'F': // Forward

digitalWrite(in1, HIGH);

digitalWrite(in2, LOW);

break;

case 'B': // Backward

digitalWrite(in1, LOW);

digitalWrite(in2, HIGH);

break;

case 'S': // Stop

digitalWrite(in1, LOW);

digitalWrite(in2, LOW);

break;

case '0'...'9': // Speed 0-9

int speed = map(cmd-'0', 0, 9, 0, 255);

analogWrite(enA, speed);

break;

}

}

}

Troubleshooting

Motor Not Moving

- Check enable jumpers are in place

- Verify motor power supply is adequate

- Test with direct battery connection

Overheating

- Ensure heatsink is properly attached

- Reduce current draw (smaller motors)

- Add cooling fan if needed

Erratic Behavior

- Add 100μF capacitor across motor terminals

- Separate logic and motor power supplies

- Check for loose connections

Related Posts

MG90S Mini Digital 180° Servo

MG90S Mini Digital 180° Servo

Metal Gear, 2.2kg·cm Torque for RC and Robotics

Introduction

The MG90S is a compact di...

Flex Sensor 5.6 cm (Detect Bending Motion)

Flex Sensor 5.6cm

Bend Detection Sensor for Arduino and Wearable Electronics Projects

Introduction

The 5.6cm...

Guide for HC-SR04 Ultrasonic Distance Sensor Module

HC-SR04 Ultrasonic Distance Sensor Module

Precise Non-Contact Distance Measurement for Arduino Projects

Introduction

...

Guide to 5-Channel Flame Sensor Module

5-Channel Flame Sensor Module

Multi-directional Flame Detection for Arduino and Robotics Projects

Introduction

The 5...

Recent Comments